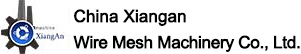

FIBERGLASS WIRE MESH WARPING MACHINE

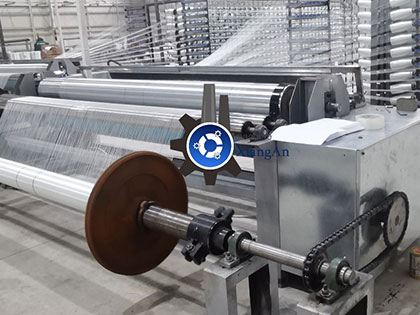

FIBERGLASS WIRE MESH WEAVING MACHINE

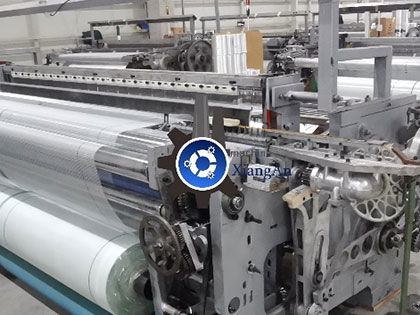

FIBERGLASS WIRE MESH COATING MACHINE

The Machine Video Link

1.What’s the fiberglass mesh

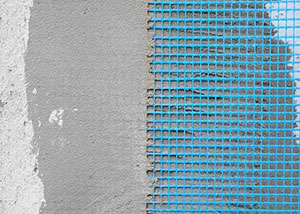

The fiberglass mesh is based on medium-alkali or alkali-free fiberglass yarn woven, and is coated with alkali-resistant polymeric emulsion. The fiberglass mesh feathers: high strength ,low weight and good alkali resistance

2.What’s the fiberglass use

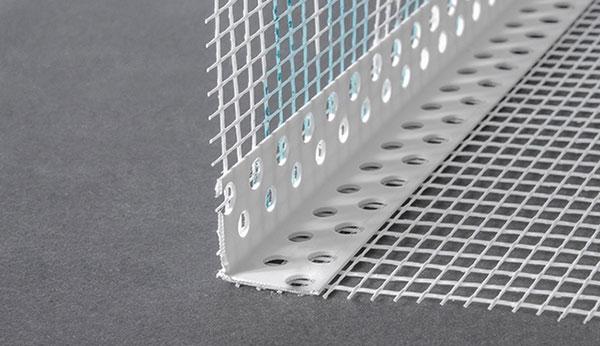

Because of its feathers,the fiberglass is used for reinforcement surfaces plaster, installation leveling floors, waterproofing, restoration of cracked plaster, and reinforcement internal wall ,ceiling surfaces and the corners of the room.

3.What’s the fiberglass mesh parameter

Weight: 90, 120,140, 145 , 160, 165, 180, 185g/m2.

Mesh shape: square.

Mesh size : 4 × 4mm, 5 × 5mm—10 × 10mm.

Color: White, yellow, blue, green, red, orange.

- How is the fiberglass mesh produced ?

1st step :Fiberglass mesh warping machine

Our XiangAn fiberglass mesh warping machine is to wind the fiberglass yarn from the bobbin onto the warp beam ,our machine has an advanced tension control system, which can make the tension of each yarn uniform on the warp beam, to ensure that the woven mesh is uniform and square.our machine has an advanced detection system. Once the yarn is disconnected, the machine will automatically stop immediately, and there will be no loss of yarn.

2nd step Fiberglass mesh weaving machine

The fiberglass mesh weaving machine weaves the yarn on the warp beam to be mesh.

Our XiangAn fiberglass mesh weaving machine has stable and durable structure, reasonable design, fast weaving speed, simple operation and easy maintenance.

3rd step Fiberglass mesh coating machine

After the yarn is woven into mesh, the yarn at the intersection is not stable enough. Then the mesh will pass through acid and alkali resistant polymeric emulsion and dried with high temperature and hot air. At this time, the mesh becomes tight and becomes to be the finished product.

Our XiangAn fiberglass mesh coating machine’s air duct is scientifically designed, with lower energy consumption and higher output. The automatic roll change design makes it easy for workers to operate and greatly improves the output.