Metal wire mosquito mesh machine/window screen weaving machine/false seiling wire mesh weaving machine.

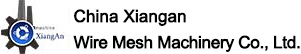

Our mosquito mesh machine can weave Gi wire,Iron wire,AL alloy wire,SS wire. Weaving width can reach 3meter wide, the mesh has high tension and smooth surface. Because of high tension, the mesh grid is very firm and fine.

The weaving method is shuttle less, but the mesh edge is closed, like shuttle machine mesh.

The shuttle less machine advantage than shuttle machine:

Each 5mins, the wire of shuttle will wear out, the operator need stop machine and change another full shuttle, so usually one operator only operate 1-2set shuttle machine.

Shuttleless machine don’t have shuttle, So the machine needn’t to stop each 5mins, then it increase the capacity and one operator can operate 15-25set shuttle less weaving machine.

The Machine Video Link

| Model | Metal wire mosquito mesh machine/window screen weaving machine |

| Mesh Density | 10-60 |

| Wire Diameter | 0.1-0.5mm |

| Frames | 2 |

| Wire Materials | Nickel Wire, S’Steel Wire, Galvanized Wire, Alufer Wire etc |

| Reed Space/Width | 1300mm/1600mm/2000mm |

| Crank Rpm | 90-120r/min Controled by VFD |

| Driving Mode | Electrical motor, V-belt, Crank |

| Gripper | Carbon Fiberglass/Nylon |

| Collection | Rubber Roller-Endless Collection Way |

| Engine Power | 2.2KW-3.0KW |

| Weight | 3.5Ton-4.5Ton |

False ceiling wire mesh weaving machine

Our false ceiling wire mesh weaving machine has high wires tension control system,and high tension can make mesh grid firm and fine, the weft wires and warp wires are all straight.

Machine weaving method is shuttle less, but the mesh edge is closed, like shuttle machine mesh.

The shuttle less machine advantage than shuttle machine:

Each 5mins, the wire of shuttle will wear out, the operator need stop machine and change another full shuttle, so usually one operator only operate 1-2set shuttle machine.

Shuttleless machine don’t have shuttle, So the machine needn’t to stop each 5mins, then it increase the capacity and one operator can operate 15-25set shuttle less weaving machine.

| Model | False ceiling wire mesh weaving machine |

| Mesh Density | 1-20 |

| Wire Diameter | 0.1-0.8mm |

| Frames | 2 |

| Wire Materials | Galvanized Wire, Alufer Wire etc |

| Reed Space/Width | 1300mm/1600mm/2000mm |

| Crank Rpm | 90-120r/min Controled by VFD |

| Driving Mode | Electrical motor, V-belt, Crank |

| Gripper | Carbon Fiberglass/Nylon |

| Collection | Rubber Roller-Endless Collection Way |

| Engine Power | 2.2KW-3.0KW |

| Weight | 3.5Ton-4.5Ton |

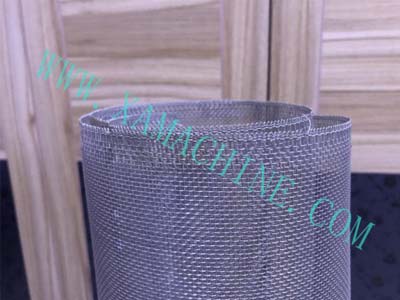

Security Window Screen Weaving Machine

Security window screen is Heavy duty SS wire mesh, It can hold heavy strike and protect your home. Usually its wire is SS,the wire diameter is 0.5-1mm

It can be installed on the window and the door.

| Model | Security Window Screen Weaving Machine |

| Mesh Density | 10-60 |

| Wire Diameter | 0.1-0.5mm |

| Frames | 2 |

| Wire Materials | Nickel Wire, S’Steel Wire, Galvanized Wire, Alufer Wire etc |

| Reed Space/Width | 1300mm/1600mm/2000mm |

| Crank Rpm | 90-120r/min Controled by VFD |

| Driving Mode | Electrical motor, V-belt, Crank |

| Gripper | Carbon Fiberglass/Nylon |

| Collection | Rubber Roller-Endless Collection Way |

| Engine Power | 3KW-5.5KW |

| Weight | 45Ton-10Ton |

The Auxiliary Machines.

1 Wire Warping Machine

The Wires need to be warped to be on the Warping Beam from the Bobbins.

2.Wire Rewinding Machine

It can rewind the little bobbin to be a big one, and the wires on the bobbin is not symmetrical, and easily break, so in order to reduce the wire breaking on weaving or warping, you need to rewind the bobbins.

3.Warping Beam Carrier

It can carry the full wire beam to the weaving machine.

4.Wire Mesh Cutting Machine

Wire mesh cutting machine can cut the mesh to be some strips.

5 Wire Join Machine

This machine can join the SS wire together.Diameter from 0.1-0.7MM

https://youtu.be/fi5EJddUhrU